13. Bullets and Rifling

Bullets predated cartridges by centuries. But the first guns launched more primitive projectiles. During the 1300s, when firearms were new to warfare, hostilities turned lethal at very close range. Even after 17-horse teams drew big bronze culverins to the battlefront, hand-to-hand combat still accounted for most of the casualties. Arrows added reach to the sword and the pike. For the first soldiers bearing guns, accuracy mattered less than noise and smoke. In cannons, a load of rocks or metal scrap flew far enough to count. Iron balls wrought such devastation that they were outlawed in central Europe.

Lead became popular with shooters beginning in the fifteenth century. Lead’s high density meant it had great inertia. Lead bullets held their speed against the push of the air, and they weren’t easily stopped by obstacles like doors, saddles, and armor. Lead’s low melting point made for easy molding to various bore sizes. It also made possible the use of rifling—spiral grooves cut into the bore to impart spin to a ball or a bullet. Lead ‘took’ the rifling as hard metal would not, the lands between the grooves engraving the surface of the bullet. For the Pilgrims, lead was a precious commodity. It remained so as frontiersmen pushed onto the plains. Rifles built in rural American shops were given small bores to conserve lead. No other material had lead’s momentum. Lead balls were accurate and lethal. Under-sizing balls for use with a patch made them faster to load in dirty bores. A clean .50-caliber rifle may shoot accurately with a ball sized to .500, but after a few shots fouling can render it all but impossible to load with a bore-size ball. A .490 ball in a snug-fitting patch usually flies as accurately as a .500 ball in a clean bore and may outperform it after a few shots.

Fouling impairs accuracy. Push patches only one way until the bore is clean enough to oil.

During the 1830s, when percussion ignition began to replace flint and the short, heavy, big-bore Plains rifle was edging out the elegant Kentucky in the West, conical bullets surged in popularity. At first, target shooters found the conical “picket” ball difficult to load and sensitive to loading technique. Alvin Clark invented the false muzzle in 1840, enabling riflemen to start a bullet square with the barrel proper. Paper-patched bullets and false muzzles soon became the choice in competition. But on the frontier patched balls remained popular. In fact, many frontiersmen chose smoothbore guns because they were faster than rifles to load and slower to foul!

A conical bullet in a smoothbore gun holds its velocity better than a ball because it has a higher sectional density (essentially, a ratio of weight to diameter). But its speed is wasted if it doesn’t hit where it is aimed. A bullet shot from a smooth bore is likely to lose its point-forward orientation. It may even tumble. Once it starts to wobble, it loses the advantage of its sectional density because it is flying part of the time at an angle to the target, and is thus wasting some of its energy. Rifling prevents tumbling by stabilizing the bullet in flight, like a football thrown by a quarterback or a top spinning on a counter. The more perfect the rotation of the football, the farther and straighter it flies. The top remains upright until its speed of rotation drops below a certain threshold. Then it wobbles and falls down.

Loading a groove-diameter bullet from the muzzle of a rifled barrel is hard work because you’re engraving the bullet with the lands all the way. And a bullet’s shank puts up much more resistance than does the modest bearing surface of a ball. Patches don’t wrap neatly on bullet shanks either. In 1826 Henri Gustave Delvigne of France attacked the problem of front-loading bullets with a new chamber design. His chamber had sharp corners that arrested and upset an undersize ball as it was rammed home. But the balls and bullets expanded to groove diameter in this process were also deformed. A chamber peg devised by another Frenchman, Thouvenin, gave similar results. In 1834 Captain Bernier of the British Brunswickers resurrected a century-old design to come up with a two-groove rifled bore and a ball with a belt that fit into the grooves. Originally proposed by a Spanish army officer, this arrangement required that the ball be oriented each time; still, pushing it home was easy. Shortly thereafter, English gun maker William Greener developed an oval ball with one flat end. A tapered hole from the flat end to the center of the ball held a metal peg whose round head conformed to the shape of the ball. Either end could be placed in the muzzle first. At launch, the peg drove into the undersize ball, expanding it to fit the grooves.

Soaked patches loosen fouling; brushes remove it. Dry patches, then oiled, should follow.

About this time, other British gun makers experimented with out-of-round bores that spun a bullet without engraving it. They didn’t pass muster in military trials because the bullets had to be perfectly sized and oriented precisely. Producing out-of-round bullets also proved difficult. Delvigne took another route in 1841, with a hollow-base bullet sized to fit the grooves. Expanding gas would seal the bullet’s skirt against the rifling. British Colonel Brunswick followed with a metal skirt soldered to the base of a ball. But these projectiles, like those upset by special chambers, often tipped in flight. British General John Jacobs came up with a four-finned bullet he mated to four-groove rifling. Failing to win a government contract, Jacobs invented a heavy conical bullet for long shooting and a 32-bore double rifle that fired an exploding bullet. African explorer and elephant hunter Sir Samuel Baker chose instead a 4-bore Gibbs with standard rifling. Its 36 inch barrel had two grooves, pitched one turn in 36 inches. As was customary then, the grooves were broad, the lands narrow to facilitate loading. (Barrels for patched balls had broad lands and narrow grooves to give more support to the undersize ball.) Baker’s rifle used 16 drams of powder to hurl a 4-oz conical bullet. Recoil was at the nose-bleed level.

In 1847 French Captain Claude-Etienne Minie (pronounced me-nay) designed a bullet with an iron cup in its hollow base. Powder gas drove the cup forward, expanding the bullet into the rifling. Expansion was sometimes so violent, however, that it cut the bullet in two, leaving a ring of lead in the bore. Captain Minie modified his design and tested it against balls from smoothbore muskets. At 100 yards musketeers hit a 6x20-foot target 149 times out of 200 shots. Riflemen shooting the Minie bullet scored 189 hits. At 400 yards he recorded 9 hits for the muskets, 105 for the rifles. Minie would later sell his conical bullet to the British military establishment for 20,000 pounds. William Greener protested and was awarded 1,000 pounds for the base-expansion idea. Minie’s bullet, lubricated with mutton fat or beeswax, became issue ammunition for the Union Army’s Enfields during our Civil War. At first a wooden plug was placed in the bullet’s hollow base to prompt expansion. This proved unnecessary.

Seeking more effective ammunition for its troops in 1854, the British government contracted with Joseph Whitworth. A brilliant technician, Whitworth was also persuasive; he requested and got an elaborate 500-yard range for his experiments. The range was destroyed by a storm soon after completion. Whitworth had another built and proceeded to try various rifling types and twist rates. Standard twist in military rifles then was 1-in-78 (one bullet rotation in 78 inches of travel). Whitworth found a better spin for short bullets was 1-in-20. Skeptics thought the sharp pitch would retard the bullet, but a hexagonal bullet of Whitworth’s own design gave more than twice the penetration of a standard ball from a slow-twist barrel. His small-bore hexagonal bullets flew flat and at long range drilled groups a sixth the size of those shot with patched balls. Hexagonal bullets, however, were costly to make and slow to load.

Whitworth’s efforts inspired more work on bullets and rifling. William Greener experimented with narrow-land rifling pitched 1-30, which stabilized small-bore (.40 to .52) bullets to 2,000 yards. Gun maker, James Purdey built two rifles featuring Greener-style barrels in 1856. He called them “Express Train” rifles because of their great power. “Express” became a common descriptor of potent British hunting cartridges.

Breech-loading mechanisms eliminated the need for an accurate bullet that could be loaded from the front. Bullets inserted from the rear could be made harder and longer and cast to full groove diameter. Hard bullets could be stabilized with shallower grooves and thus driven faster. Sharp rifling pitch could be used— even rifling that varied in pitch and depth, breech to muzzle. William Ellis Metford experimented with “gain twist” that allowed a bullet easy acceleration from the chamber but increased rate of spin during its barrel travel. His 34 inch barrel produced an exit spin of 1-in-17 but started bullets so gradually they turned over only once before reaching the muzzle! Metford favored the wide, shallow grooves that now work well with jacketed bullets. He also developed segmented rifling, with rounded lands and grooves. By the end of the century, gain twist and progressive grooving (deeper grooves at the breech than forward, as in England’s Enfield and Martini-Henry rifles) were largely abandoned.

Charles Newton, American inventor, gun maker and wildcatter, reasoned that since a bullet bears on only one shoulder of a land, the other is unnecessary. His “ratchet rifling” tested this concept. Like the Lancaster oval bore derived from Bernier’s elliptical design, Newton’s idea had merit but did not succeed at market. To reduce bullet deformation that can lead to inaccuracy, Marlin introduced “Micro-Groove” rifling with 16 narrow, shallow grooves. They deliver excellent accuracy and have become a trademark of this venerable firm. But Marlin also uses Ballard-style six-groove rifling in its centerfire rifles.

Metford-style rifling features wide groove bottoms with the same radius as the bullet. They meet flat-topped, square-shouldered lands. Popular since its application in two-groove Springfields during World War I, Medford rifling has been adopted by many commercial makers, who commonly now use four and six grooves. Heckler and Koch rifles wear polygonal rifling.

A bullet’s rotation is determined by rifling twist, expressed as distance traveled per revolution. A 1-in-14 twist means the bullet turns over one time for every 14 inches of forward travel. If all bullets were the same weight and shape and traveled at the same speed, one rate of twist would work for all. That’s not the case, however. Proper twist rate varies. A patched round ball in a muzzleloader requires a slow twist, while a long bullet in small-bore rifle cartridge needs a quick twist to stabilize. Proper rate of spin for the muzzleloader might be 1-in-66 for a round ball, 1-in-32 for a conical bullet. Some muzzleloaders are rifled 1-in-48 as a compromise. Rifles designed for long .264 rifle bullets may have twist rates as short as 1-in-9.

A popular twist for 80-grain match bullets in the.223 is 1-in-7-½.

Wayne was pleased with this one-hole group, shot with a Nesika rifle in .20 Tactical.

Wayne drilled this 5/8 inch group with a .375 Blaser R93 and Norma ammo. Oryx bullets.

A .308 bullet spun one turn in 12 inches at a muzzle velocity of 3,000 fps reaches an animal 400 yards away in about half a second. (Average velocity: just under 2,500 fps.) In that half second, the bullet spins 1,500 times. Give it a 1-in-9 twist, and you boost rotational speed by 25 percent, to 3,750 rotations per second. Unlike a bullet’s forward speed, which slows under the influence of drag, rotational velocity remains essentially constant. It affects the reaction of bullets to twigs and other obstructions in flight, and the expansion of softnose bullets in game. Jacket petals spread far to the side during upset add drag to both forward and rotational movement. So besides reducing penetration, they slow bullet rotation, reducing stability. Petals also act as lever arms to tip the bullet. They do inflict greater terminal damage because of their rotation—damage evident in high-speed film footage of bullets tearing ballistic gelatin. Contrary to what some shooters think, though, there’s limited “buzz-saw” effect. A .308 bullet turning once in every 12 inches of travel barely gets through one revolution while penetrating the chest of a big deer.

In 1879 British ballistician Sir Alfred George Greenhill announced a formula to derive proper spin for all bullets with specific gravity 10.9. As the specific gravity of pure lead is 11.4, most jacketed bullets come close enough. Greenhill’s formula was first published in the British Textbook of Small Arms, 1929: Required twist in all calibers equals 150 divided by the length of the bullet in calibers.

Thus, proper spin for a 180-grain .308 bullet 1-¼ inch long is 150/4=37.5. Remember, 37.5 is caliber. To convert to inches, you multiply it by .308. Answer: just over 11 inches. Most .30-caliber barrels are rifled 1-in-10 or 1-in-12, so the formula confirms they have a useful pitch for that bullet at the speeds we launch such bullets from .308, .30-06, and most .300 Magnum rifles. Most modern barrels have proper twist for common bullet weights. Top accuracy can be hard to achieve with small-bore rounds loaded with a wide range of bullets. The .223, for example, is chambered in rifles with barrels rifled from 1-in-14 to 1-in-7-½. Varmint bullets of 50 to 53 grains work just fine with a mild twist rate; but 75- and 80-grain match bullets require special fast-twist barrels.

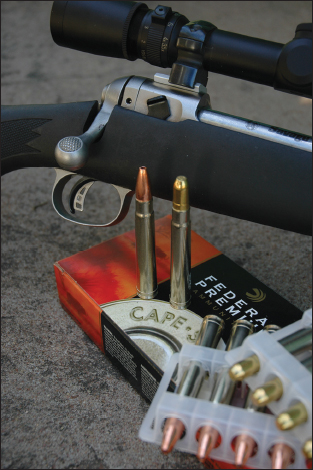

Federal offers excellent heavy-game loads, with solid and softpoint bullets, for the .375 H&H.

The .22-250, a flat-shooting varmint cartridge, gave Wayne these groups, from a Remington 700.

Even gentle twist rates induce dizzying spins. A .308 bullet rotating one turn every 12 inches at a velocity of 3,000 fps rotates 1,500 times during a half second and 400 yards of forward travel. In contrast, an ordinary V-6 engine propelling an automobile at 65 mph turns perhaps 3,000 rpm. That’s 50 crankshaft rotations per second, or just 25 per half-second!

Perfect, on-axis rotation is hard to achieve with bullets. The violent thrust accelerating them from a stand-still to 3,000 fps in an eye-blink puts great stress on core and jacket. Deformation from the rifling that imparts the spin can also make the bullet shudder. So can a damaged muzzle, a nicked bullet base or lack of concentricity in the jacket. The rotation of a bullet’s nose into its own orbit around the bullet’s axis is called precession. Of course, this is undesirable; but like a top that “goes to sleep” after you give it a hard spin, the bullet may rotate more smoothly, with less precession, after covering some distance. That’s why sometimes you get smaller groups (in minutes of angle) at long range. A rifle that shoots into 1-½ inches at 100 yards may keep all bullets inside 3 inches at 300 yards.

Yaw is another aberration in bullet flight. It occurs when the bullet’s axis does not line up with its direction of travel. Like precession, yaw is exacerbated by rifling with too sharp a pitch, or rate of twist.

Lapua round-nose softpoints drilled this group for Wayne, from a Savage Model 10.

Table of contents

- Title Page

- Dedication

- Copyright

- Acknowledgments

- Foreword

- CONTENTS

- INTRODUCTION

- SECTION I: BALLISTICS IN HISTORY

- SECTION II: THE MUSCLE BEHIND THE SHOT

- SECTION III: BULLETS—THE INSIDE STORY

- SECTION IV: SPEED, ENERGY, AND ARC

- SECTION V : PUTTING BALLISTICS TO WORK

- SECTION VI: FOR LONGER REACH

- BALLISTICS TABLES FOR MODERN SPORTING RIFLES

- GLOSSARY