22. More on speed

The first instruments to gauge bullet speed were mechanical—notably Robins’ pendulum in the eighteenth century. Movement of the pendulum when it was struck gave Mr. Robins the information he needed to calculate the bullet’s speed, because speed is a component of momentum. We no longer measure velocity with pendulums, but with electric eyes that register the passage of a bullet’s shadow as the bullet travels a known distance. The device is a chronograph.

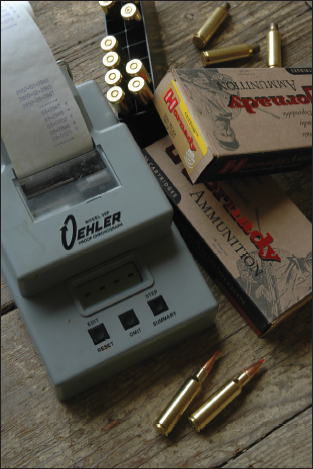

Chronographs are a century old, but it wasn’t that long ago that Texan Dr. Ken Oehler designed and built the first chronographs meant for consumer use. Before Oehler’s instruments, chronographs were found only in the laboratories and shooting tunnels of ammunition companies. They were fixed in place. They were very costly. Consequently, shooters could only take the catalog ballistics charts at face value, and hope their handloads were producing the pressures and bullet speeds listed in the loading manuals. Now every serious shooter I know has a chronograph. Portable and easy to use, some are less expensive than an ordinary rifle-scope!

Dick Williams set up a Chrony chronograph. Reading velocities is essential in tuning handloads.

One of the first riflemen to test the .300 RCM, Wayne used an Oehler 35 chronograph.

Portable chronographs have “screens”—electric eyes—set up a short distance apart on a bar or even directly on the electronic box that gives you a velocity reading. The chronograph measures the time (hence, “chrono”) between the bullet’s passage over the first screen and its passage over the second. Just as you could drive a car a quarter mile and compute the number of miles per hour your car would travel at that speed, so you can time bullet flight for a short distance and extrapolate. Some chronographs allow you to adjust the distance between screens. The greater the distance, the more accurate the read. The chronograph must be precisely calibrated for the span between screens, or it won’t read velocities correctly. Also, you must shoot squarely through the opening above the screens, as an angled shot, horizontally or vertically, effectively increases the distance the bullet travels during its timed flight.

You get lots of information from a chronograph: bullet speed for each shot, of course, but also average bullet speed for a string of several shots. The average, or mean velocity, is the sum of all recorded velocities divided by the number of shots you fired. The instrument will also tell you the extreme spread (ES)—that is, the range of velocities, slowest to fastest. ES is useful because you want a load that delivers uniform velocity. While it’s unrealistic to expect all shots to stay within 5 fps of each other, I’ve often seen more than 100 fps variation between slowest and fastest readings. If a hunting load delivers good accuracy and adequate speed, and ES stays within 25 fps, that ammunition shouldn’t disappoint you on a hunt. Some loads do better; some work hard to meet that standard.

Another number you’ll get from modern chronographs is standard deviation. Credited to American statistician Karl Pearson, this statistical term appeared in the late 1890s. Without wading into mathematics, which had me in a headlock from grammar school through my PhD program, I can summarize standard deviation as the positive square root of the variance. What’s variance? It’s simply the sum of the squares of the deviations from the mean of your chronograph readings, divided by a number that’s one less than the number of times you shot. A high standard deviation indicates a lot of spread in your data—that is, a great deal of variability among your readings. A low SD means that most of your readings were clustered close to your mean.

Texas rifle-maker Charlie Sisk deftly uses a computer to asses wildcat cartridge performance.

There’s more to milk from standard deviation. With it, you can construct a bell curve that shows how your velocities grouped around the mean, and, for any given speed range, the percentage of shots likely to fall within that range. Occasionally you’ll get a velocity reading you don’t believe. It may be the chronograph didn’t register the bullet’s passage properly. Or the load was somehow defective. One rule of thumb to keep SD useful: Throw out any reading more than 2 ½ times the SD from the mean.

Bullet velocity varies not only with the powder type and charge and bullet weight; it’s influenced by chamber and barrel dimensions, throat shape and length and bore finish. A tight chamber reduces the amount of energy lost in case expansion. So does a tight throat. But a long throat that allows the bullet to move before engaging the rifling and permits long seating of the bullet to increase powder space enables a handloader to add fuel, boosting velocity. That long throat is generally thought to be less than desirable for accuracy; but on hunting rifles it’s not a liability. Roy Weatherby used long throats and ambitious Norma loadings to give his magnums lots of pep. My pal John Burns, one of the principals in GreyBull Precision, insists that long throats cut to a minimum diameter sacrifice no accuracy but give you more throttle than the short throats commonly associated with target rifles.

Bore dimensions and rifling type affect pressures and bullet speed. Some barrels seem to “shoot faster” than others that by all appearances should give the same performance. Bore finish is pretty much invisible, but you can feel it. The consensus of many barrel-makers is that smooth lands and grooves boost accuracy. “But you can get a bore too smooth,” one pointed out. “If you make it glass-smooth, you increase friction. It’s sticky, like the surface of a glass table.” Increased friction means higher pressures, which can increase speed; however, if your ammunition already tops the velocity charts, cork-popping pressure is not what you want. More velocity without higher pressure is the goal.

Barrel length also makes a difference in bullet speed. How much difference per inch depends on the original and finished lengths, the original velocity, the cartridge and powder and bullet. The only way to tell for sure how much velocity you gain with a long barrel or lose with a short barrel is to chop a very long barrel shorter an inch at a time. Such tests show great variation. One, conducted by A-Square with a .300 Winchester pressure barrel, measured velocities at 1 inch increments from 28 down to 16 inches. Loads of 70.5 grains IMR 4350 with a 150-grain Nosler Ballistic Tip, and 78.0 grains RL-22 with a 180-grain Sierra Spitzer gave these results:

Velocity loss per inch of barrel length varies from a low of 22 fps to a high of 56 fps for the 150-grain bullet, and 18 fps to 63 fps for the 180-grain bullet. That range could be expected to vary with other .300 Winchester Magnum loads. Certainly it would differ for other cartridges with faster-burning powders. Note that rate of velocity loss increases substantially as the barrel is lopped to less than 20 inches in length.

Logic tells us that we’re cutting into the descending sector of the pressure curve, before it flattens out. A lot of pressure is being released to the atmosphere instead of staying in harness behind the bullet. Based on the figures presented here, you lose relatively little speed and energy chopping a barrel from 24 to 22 inches.

Hornady’s .300 and .338 RCM cartridges were designed to deliver high speeds in carbine-length barrels. The cutting-edge propellants in these rounds are also used in the company’s Superformance ammo. No doubt that powder technology will find its way into other loads, industry-wide. Expect a shift in the conventional ballistic wisdom that has favored long barrels over short.

Changing components affects pressures and velocities. Substituting magnum primers for standard primers, for example, can hike pressure by several percentage points. At full throttle, increasing pressure (by whatever means) kicks velocity up a little—but not proportionately. Similar changes occur when you substitute cases with smaller powder chambers (thicker walls or webs). Pressure goes up; velocity follows but not at the same rate. Switching bullets, you may see no significant change in velocity. However, if the new bullet has a longer shank and generates more friction in the bore, or is seated closer to the lands on take-off, or is very slightly larger in diameter, or has a “sticky” jacket, pressures can rise. Remington’s use of Nosler Partition bullets for the first .300 Ultra Mag loads no doubt disappointed the folks at Swift, who were already supplying Partition-style A-Frame bullets to Remington. The rationale: A-Frame jackets were softer, resulting in more bore friction and higher pressures. To get 180-grain bullets going as fast as they wanted them too in the new Ultra Mag, Remington engineers chose the Noslers.

This Swarvoski-scoped Remington 700 is chambered to the fast-stepping 7mm Ultra Mag.

Table of contents

- Title Page

- Dedication

- Copyright

- Acknowledgments

- Foreword

- CONTENTS

- INTRODUCTION

- SECTION I: BALLISTICS IN HISTORY

- SECTION II: THE MUSCLE BEHIND THE SHOT

- SECTION III: BULLETS—THE INSIDE STORY

- SECTION IV: SPEED, ENERGY, AND ARC

- SECTION V : PUTTING BALLISTICS TO WORK

- SECTION VI: FOR LONGER REACH

- BALLISTICS TABLES FOR MODERN SPORTING RIFLES

- GLOSSARY